Similar

The street railway review (1891) (14761436085)

Summary

Identifier: streetrailwayrev04amer (find matches)

Title: The street railway review

Year: 1891 (1890s)

Authors: American Street Railway Association Street Railway Accountants' Association of America American Railway, Mechanical, and Electrical Association

Subjects: Street-railroads

Publisher: Chicago : Street Railway Review Pub. Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

Text Appearing Before Image:

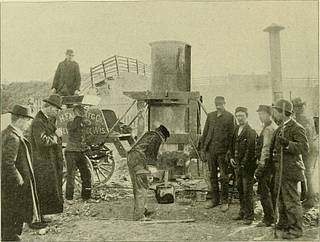

a 750 (^ti^if^aiWay-9\^ mariners compass so that it is always kept level eventhough the wagon may be standing on a grade. Behindthe cupola is a small steam engine with a water tubeboiler. The engine takes care of itself to a large extentas the water feed is automatic being regulated by theheight of the water in the boiler. The oil fuel flow isregulated by the pressure of steam. The engine drivesa blower for furnishing an air blast to the cupola. Theair pipe between the blower and cupola has a flexible a pair. Before the molds are applied the rails near theends are cleaned and if the ends do not butt togetherclosely a thin section of rail is driven in to fill the crack.The molds are then put around the joints. The iron isthen poured in the molds from a ladle as in an ordinaryfoundry. The union between the iron and steel of therail is similar to that which takes place in a good weldand hence the term cast-welding is applied to the processby the Falk company. Sections through joints and

Text Appearing After Image:

METAL RUNNING. joint to allow for the movement of the cupola on itspivots. Under the engine can be seen the tank for watersupply. In operation the first thing, of course, is to dig up thepaving and expose the joints. Meanwhile the moldswhich are of common cast iron are thrown in a heapsomewhere near by and a fire built around them so thatby the time they are to be put around the joints they area dull red. The molds are lined with a composition ofgraphite and another substance the nature of which isnot given out. This composition is applied with anordinary paint brush. The molds are relined in this wayfor about every 20 joints cast in them. They can belined while hot and it takes about half a minute to reline pieces of casting broken off show that the same state ofunion exists as with a good weld. As shown in the engravings the molds have eyeboltsso that they can be handled with iron hooks. They areheld in place with ordinary clamps and are of such shapeas to fit up snugly against the

Tags

Date

Source

Copyright info