Similar

Cyclopedia of textile work - a general reference library on cotton, woolen and worsted yarn manufacture, weaving, designing, chemistry and dyeing, finishing, knitting, and allied subjects (1911) (14596113607)

Summary

Identifier: cyclopediaoftext05amer (find matches)

Title: Cyclopedia of textile work : a general reference library on cotton, woolen and worsted yarn manufacture, weaving, designing, chemistry and dyeing, finishing, knitting, and allied subjects

Year: 1911 (1910s)

Authors: American School (Lansing, Ill.)

Subjects: Textile fabrics Textile industry

Publisher: Chicago : American school of correspondence

Contributing Library: Claire T. Carney Library, University of Massachusetts Dartmouth

Digitizing Sponsor: Boston Library Consortium Member Libraries

Text Appearing Before Image:

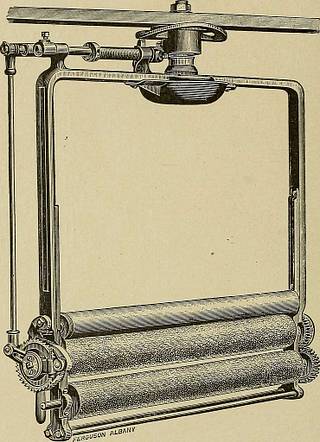

Fig. 18. Take-Up and Parts. bottom of the frame. The spreader bow is supported and rotatedby the vertical shaft. The weight of the take-up is supported bya hardened rounded steel collar (not shown in the cut) seated in ahardened steel cup, 5. This is sufficiently free to allow the take-up to move readily without leaving it too free to continue rotatingafter the stop motion has released the shipper. The bevel pinion 11,on top of the frame takes its motion from the standing gear 9, onthe crosstree and by means of the crank 32, and spring connectingrod 33 and 31, reciprocates the dog 24, engaging the ratchet gear 49 38 KNITTING. 17, on the end of the upper quartz covered roll 13. When thetension on the cloth is rightly adjusted the unnecessary take-upmotion is absorbed by the spring and as the adjustment of thisspring connecting rod device determines the degree of tension on

Text Appearing After Image:

Take-Up, Outside Drive. the cloth while being knitted, and is a most important factor inproducing good cloth with a minimum of broken needles, detaildrawing is given in this, diagram. The crank connection 32, is attached to the upper end of theconnecting rod 31 ; on the other connecting rod 31, is a cylindrical 50 KNITTING. 39 spring 32. These two rods are held together at either end by con-necting links 28, securely fastened to one of the rods, but allowingthe other rod to move freely through the other holes in the links ?^j4?rf-

Tags

Date

Source

Copyright info