Similar

1914 illustrated and descriptive catalog of Whitin cotton waste machinery and of various systems of working cotton waste (1914) (14798698713)

Summary

Identifier: 1914illustratedd00whit (find matches)

Title: 1914 illustrated and descriptive catalog of Whitin cotton waste machinery and of various systems of working cotton waste

Year: 1914 (1910s)

Authors: Whitin Machine Works (Whitinsville, Mass.)

Subjects: Cotton machinery

Publisher: Whitinsville, Mass. : Whitin Machine Works

Contributing Library: Claire T. Carney Library, University of Massachusetts Dartmouth

Digitizing Sponsor: Claire T. Carney Library, University of Massachusetts Dartmouth

Text Appearing Before Image:

Condenser which takes oft 80to 96 good ends for the 48 width machine, and single or doubleapron rubs using the ring doffer. The spools of roving can be spunto advantage on any one of three separate types of spinning frameswhich we have developed to meet the various demands of wastespinning. In this connection it is interesting to note that by ourpresent methods on the Condenser System it is possible to makeyarns of low grade waste at least 25% finer in numbers and atconsiderably less labor cost than has been possible heretofore bythe use of the woolen system. On pages 81 to 91 plans and descriptions of several equipmentsare shown which will give an idea of the kind and amount of ma-chinery required to use up various grades of waste. For the infor-mation of those interested, we are showing three complete unitsfor spinning yarn; also one for converting roving and spinnerswaste into sliver; and one for reclaiming the long fibres from cardstrips, etc. /f^ ^r?T Page 11 Preparation ofStock

Text Appearing After Image:

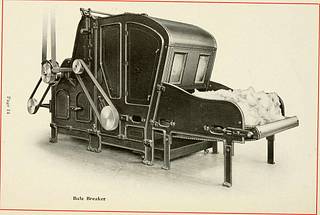

BALE BREAKER This Machine is designed for the purpose of opening the stockfrom the bale. Where any great amount of stock is to be handled,the machine can be placed in the warehouse, and as the stock passesthrough the machine, it can be distributed or exhausted to the binsin the cleaning and mixing department. The Production of this machine is from 15,000 to 20,000 lbs.in 10 hours, and it delivers the stock to the next process opened inthe best possible condition. Speed of main shaft 450 r. p. m. Size of pulleys 12 x 2;.Horse Power consumption is from -4 to 5 horse power.Belting Required: Pin apron belt 9, 3 of 3 belting.Feed and Delivery apron belt 17, 0 of 2; belting.Extras: Fans and Exhauster system,Traveling aprons and Conveyer system.Floor Space: 13, 8 x 5, 10;.Weights: Net Weight 4500 pounds,Shipping Weight 4600 pounds. Page 15

Tags

Date

Source

Copyright info